Spooling Through History: Pendleton Woolen Mills

Pendleton Woolen Mills is an American textile manufacturing company whose original facilities are among the few woolen mills still in operation in the United States. A representative from the company’s corporate communications and public relations department spoke to us about Pendleton’s history and products, the textile business in the twenty-first century, and how one of the company’s shirts influenced one of the greatest bands of all time.

What did founder Thomas Kay envision for his company?

Thomas Kay came to Salem, Oregon, in 1863 and opened his own mill, the Thomas Kay Mill; his genius for fabric and craftsmanship eventually made his mill the largest on the West Coast. It turned out the first bolt of worsted wool west of the Mississippi River. Little did he know that his standard for exceptional fabric, extraordinary quality, and conducting business by the Golden Rule would continue through six generations to this present day. Pendleton’s vision statement—creating quality products that embody craftsmanship, enrich lives, and connect generations—is much the same today as it was when the company was founded. were important to them. He even lived with the tribes for extended periods of time. Blankets played an important role in the early history of the West. They were one of the few essentials in the lives of both Native Americans and pioneers, offering protection from the cold and serving as hangings, partitions, doors, awnings, and sunshades. They were also considered to be a medium of exchange—trade blankets—in a system in which the most colorful and best-quality blankets had the highest value. Native Americans remain important customers today.

Did Kay experience any hardships during Pendleton’s early years?

Any entrepreneurial business involves risks. However, during his life, textile mills were especially vulnerable to fire. Although he experienced the devastation of a number of mill fires, he overcame it by persevering, rebuilding, and restoring after each one. This perseverance allowed his heirs to open Pendleton Woolen Mills in 1909.

Why did the company decide to remain family owned?

Kay’s eldest daughter, Fannie Kay, was his trusted confidant and protégé in the mill business. It was part of her DNA to continue woolen textile manufacturing and advance the family business. Her marriage to a prominent local retailer, Charles P. Bishop, was a union that blended weaving and retailing backgrounds into what would become Pendleton Woolen Mills. Their three sons continued the business, and succeeding generations have agreed to continue the legacy of Pendleton Woolen Mills. We look forward to the next 150 years of family ownership!

The trade blanket is one of the company’s most famous products. How important is it to the company’s history? How did the relationship with the Native Americans develop?

The trade blanket is essential to our history, as it was the first product Pendleton produced in 1909. The company’s first consumers were the Native Americans living in the area: the Cayuse, Walla Walla, and Nez Perce tribes.

Why were the Beach Boys originally known as The Pendletones? Did that help raise young people?

The Pendleton wool board shirt was a staple for early surfers in the late 1950s and early 1960s. Inspired by the shirt, the band dubbed themselves The Pendletones and wore a blue-and-charcoal plaid version. on the cover of 45s and LPs throughout the 1960s while singing about the California surfing scene, even as their name changed to the Beach Boys. In 2002, Pendleton brought back the board shirt in the same plaid and renamed it the Blue Original Surf Plaid. Today, the board shirt is embraced as a staple by not only surfers but also skaters and car club enthusiasts. It is the uniform for those exploring the great outdoors, whether in nature or in the neighborhood.

Joe Rawnsley, an Englishman, was the first Pendleton blanket designer. He spent time with the tribes to learn about their cultures and the ceremonial shapes that were important to them. He even lived with the tribes for extended periods of time. Blankets played an important role in the early history of the West. They were one of the few essentials in the lives of both Native Americans and pioneers, offering protection from the cold and serving as hangings, partitions, doors, awnings, and sunshades. They were also considered to be a medium of exchange—trade blankets—in a system in which the most colorful and best-quality blankets had the highest value. Native Americans remain important customers today.

How many lines of product does Pendleton currently have? What is your most popular product?

Pendleton manufactures women’s and men’s apparel, home products (including our blankets), and accessories. We have a vibrant business in all of our product divisions. In our home category, our blankets are the most popular items. In clothing, our men’s shirts and women’s sweaters, respectively, are the most popular.

How has the textile industry changed over the last century? How has Pendleton stood the test of time to still be competitive in today’s economy?

The woolen textile industry has become more competitive since manufacturing started moving to offshore locations. However, Pendleton has remained relevant, current, and competitive by reinvesting in our mills with state-of-the-art technology and maintaining our commitment to quality, craftsmanship, and innovation.

What makes wool so amazing?

No other fiber, natural or man-made, has all the characteristics that make wool so remarkable: its beauty, its strength, its elasticity, and its ability to absorb moisture, insulate, and self-clean. Dubbed “living fiber,” wool is incredibly resilient and elastic. It can be bent 20,000 times without breaking.

In contrast, cotton can only be bent 1,800 times and rayon 75 times. It’s a natural thermostat as well, absorbing perspiration and releasing it slowly through evaporation, so it insulates to keep you warm in winter and cool in summer. Wool actually has overlapping scales, all pointing in the same direction. When heat, moisture, and pressure are applied, the scales interlock into an irreversible tangle. The resulting fabric has superb insulating qualities because wool traps air. It’s also an easy care fabric, refreshing itself when allowed to hang for twenty-four hours after each wearing. It should only be cleaned once or twice in a season unless heavily soiled.

Explain the process from raw wool to finished product:

Pendleton has long-standing, worldwide relationships with wool growers. Only the highest-quality, 100 percent pure virgin wool is selected and chosen for fineness, crimp, length, strength, and color. The wool then goes through a process called scouring, in which the wool passes gently through a duster and a series of baths and squeeze rolls to remove water, dirt, and grease. (The lanolin from this process is recovered, filtered, and used commercially in cosmetics and pharmaceuticals.) The clean wool is then dried and packed into bales, ready for dyeing.

Wool may be dyed as fibers, yarn, or fabric. Dyes are circulated by pumps, and the computer reads a sample color or generates the appropriate dye formula. Temperature and pressure are electronically controlled to produce the rich, permanent, and exact color that Pendleton is known for.

After the wool is dyed, wool fibers are combed into fine sheets and then divided into thin strands called roving. Roving fibers are smoothed and aligned for uniformity, and then wound onto large spools for spinning. The spools of roving are mounted on the spinning frame, and the roving is delivered to a bobbin, where twist is introduced to give strength to the yarn. One pound of wool can yield ten miles of spun yarn!

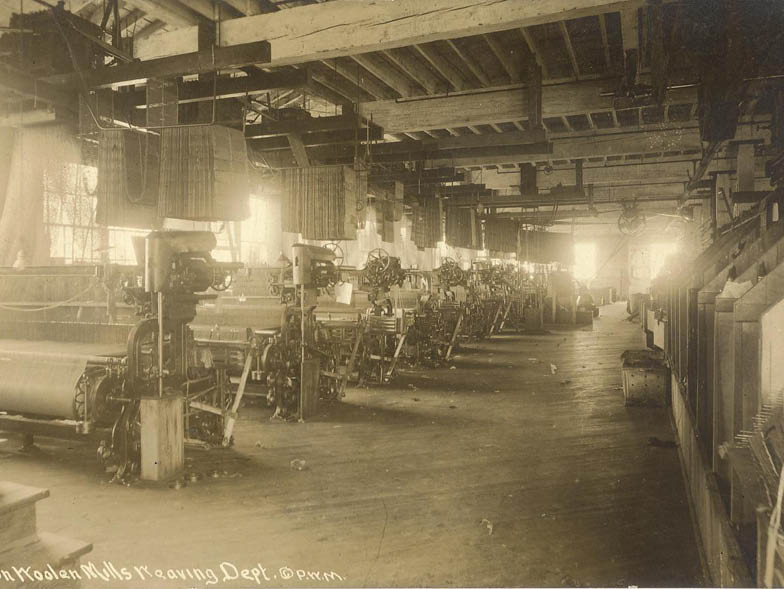

The spun yarn is now ready for weaving. Using state-of-the-art looms, lengthwise (warp) and crosswise (weft) yarns are interwoven at right angles to form fabric. Computer technology ensures a flawless execution of pattern and plaid designs. Pendleton’s computer-controlled looms can produce three hundred yards of eighty-inch shirt fabric in one day.

To finish the fabric, it goes through a process called fulling. Woolen fabric is subjected to controlled heat, moisture, friction, and pressure. The resulting shrinkage produces softer and more compact fabric. The cloth is sheared to produce a smooth, even surface and napped by a fine wire brush to create a soft, fuzzy surface.

Has production technology changed a great deal for the wool/textile industry in general?

Technology has made production faster, better, and more efficient, but having skilled craftsmen is vital to our success. It has also allowed Pendleton to develop new products, such as Pendleton Eco-Wise Wool, which was developed to leave the lightest footprint on the earth, using nontoxic dyes that make it biodegradable. Our superior-quality, 100 percent pure virgin wool passes strict standards of sustainability and responsible environmental stewardship for materials, chemicals, and processes through standards set by MBDC, a respected product and design firm promoting the application of Cradle to Cradle principles to product and building designs.

What do you think of the statement “style is cyclical”?

New generations of designers often look at styling from past decades for inspiration and give a concept a new look by reinventing and refreshing it. Consequently, the Pendleton Archive is a valuable resource for the company’s designers. Outside brands are also drawn to Pendleton for our history, heritage, authenticity, and fabric expertise. The variety of high-profile collaborations extends Pendleton brand attributes in a more contemporary light, often in unexpected ways.

How many people do you employ, and how are they distributed geographically?

We employ approximately nine hundred people in retail stores and outlets across the country; in distribution centers in Portland, Oregon, and Omaha, Nebraska; in two Pacific Northwest mills; and in our corporate office in Portland, Oregon.

“The variety of high-profile collaborations extends Pendleton brand attributes in a more contemporary light, often in unexpected ways.”

Are there any Pendleton sales/operations overseas?

We have distribution in Europe, Japan, Korea, and Australia. In addition, we have sixty retail stores and outlets in the United States, and our direct-to-consumer channels: our catalog and our website.

Why are mill tours important to the company? What can a visitor expect to see and experience on a tour?

The Pendleton Mills are the center of our business, and the tours create authenticity for the brand, giving consumers an up-close view of the wool process—dyeing, carding, spinning, and weaving—at both of our mills in Washougal, Washington, and in Pendleton, Oregon. Pendleton Mills was rated one of the nine best factory tours in 2015 by CNN.

For more info, visit pendleton-usa.com.